The Human Cost of Industrial Accidents: A Wake-Up Call for Change

Industrial accidents are a harsh reality that can have devastating consequences for workers, families, and communities. From chemical plant explosions to factory fires, these incidents can be catastrophic and deadly. In this post, we’ll explore some of the most significant industrial accidents in recent history, examine the causes and consequences, and discuss ways to prevent such tragedies from happening in the future.

The Bhopal Disaster: A Tragic Reminder of Industrial Negligence

On December 3, 1984, a gas leak at a Union Carbide pesticide plant in Bhopal, India, released toxic chemicals into the air, killing an estimated 3,787 people immediately. The total death toll is estimated to be around 15,000 to 22,000 people, with many more suffering from long-term health effects.

- Causes: The disaster was attributed to a combination of human error, design flaws, and inadequate safety measures.

- Consequences: The incident led to widespread outrage, lawsuits, and calls for stricter regulations on industrial safety.

The Rana Plaza Collapse: A Preventable Tragedy

On April 24, 2013, the Rana Plaza building in Dhaka, Bangladesh, collapsed, killing over 1,100 garment workers. The tragedy highlighted the poor working conditions and lax safety standards in the textile industry.

- Causes: The collapse was attributed to structural weaknesses, inadequate building codes, and pressure from factory owners to keep production going.

- Consequences: The incident led to international outcry, boycotts, and efforts to improve working conditions and safety standards in the industry.

The Texas City Refinery Explosion: A Lesson in Safety

On March 23, 2005, an explosion at the BP Texas City refinery killed 15 workers and injured over 180 others. The incident was one of the deadliest industrial accidents in recent U.S. history. Causes: The explosion was attributed to a combination of equipment failure, human error, and inadequate safety procedures. Consequences: The incident led to a massive fine for BP and a renewed focus on process safety and risk management.

Preventing Industrial Accidents: A Shared Responsibility

Industrial accidents are often preventable, and it’s up to all stakeholders – including industry leaders, regulators, and workers – to ensure that safety protocols are in place and followed.

- Regular Maintenance: Regular maintenance and inspections can help identify potential hazards and prevent equipment failures.

- Safety Training: Providing workers with comprehensive safety training can help prevent human error and ensure that they know how to respond in emergency situations.

- Strong Regulations: Strong regulations and enforcement can help ensure that industries prioritize safety and adhere to best practices.

What Do You Think?

Industrial accidents are a serious concern that affects us all. We want to hear from you:

- What do you think are the most significant challenges in preventing industrial accidents?

- How can industries balance productivity and safety?

- What role should governments and regulators play in ensuring industrial safety? Share your thoughts in the comments below!

Sources:

- National Institute for Occupational Safety and Health (NIOSH)

- Occupational Safety and Health Administration (OSHA)

- International Labour Organization (ILO)

Stay Safe, Stay Informed

Stay up-to-date with the latest news and developments on industrial safety and accidents. Follow us for more thought-provoking articles and discussions on critical issues that matter.

Inferno: Uncovering the Devastating Reality of Fire-Related Accidents

Fires can occur anywhere, at any time, and without warning. From domestic blazes to industrial infernos, fire-related accidents can have catastrophic consequences. Let’s explore some alarming statistics and stories behind these devastating events.

The Alarming Numbers

According to the National Fire Protection Association (NFPA), in the United States alone:

- There were over 1.3 million fires reported in 2020, resulting in 3,010 civilian deaths and 14,275 injuries.

- Home fires account for 73% of all reported fires, with cooking equipment being the leading cause of home fires.

- Electrical fires are a significant concern, with an estimated 51,000 home electrical fires occurring each year.

The Deadliest Fires in History

- The Great Fire of London (1666): This devastating fire destroyed much of the city, leaving tens of thousands homeless. While not as deadly as some modern fires, the Great Fire of London led to significant changes in building codes and firefighting practices.

- The Triangle Shirtwaist Factory Fire (1911): This tragic industrial fire in New York City killed 146 workers, mostly young immigrant women. The incident led to major reforms in workplace safety and labor laws.

- The Grenfell Tower Fire (2017): A high-rise residential building in London caught fire, resulting in 72 deaths. The tragedy highlighted concerns about building materials, safety regulations, and emergency preparedness.

Common Causes of Fire-Related Accidents

- Electrical Issues: Faulty wiring, overloaded circuits, and malfunctioning appliances can all spark a fire.

- Cooking Accidents: Unattended cooking, grease spills, and faulty appliances can quickly turn a meal into a disaster.

- Candle and Open Flame Safety: Candles, cigarettes, and other open flames can ignite nearby objects, spreading quickly.

- Industrial Accidents: Chemical reactions, equipment malfunctions, and human error can all lead to devastating industrial fires.

Prevention and Preparedness

While fires can be unpredictable, there are steps we can take to reduce the risk:

- Working Smoke Alarms: Ensure you have working smoke alarms in your home, and test them regularly.

- Fire Escape Plans: Develop a fire escape plan with your family, and practice it regularly.

- Electrical Safety: Regularly inspect your home’s electrical systems and appliances, and avoid overloading outlets.

- Safe Cooking Practices: Never leave cooking unattended, and keep a fire extinguisher in the kitchen.

Conclusion

Fire-related accidents can have devastating consequences, but by understanding the causes and taking preventative measures, we can reduce the risk. Whether it’s a domestic fire or an industrial blaze, preparedness and safety protocols can mean the difference between life and death. Let’s work together to create a safer, more fire-resilient world.

Into the Dark Blue: Uncovering the Hidden Dangers of Maritime Accidents

The vast expanse of the world’s oceans has long been a source of fascination and fear. While maritime trade is the lifeblood of the global economy, the sea can be a cruel mistress. Maritime accidents have claimed countless lives, damaged ecosystems, and disrupted global supply chains. Let’s dive into the statistics and stories behind some of the most significant maritime accidents in history.

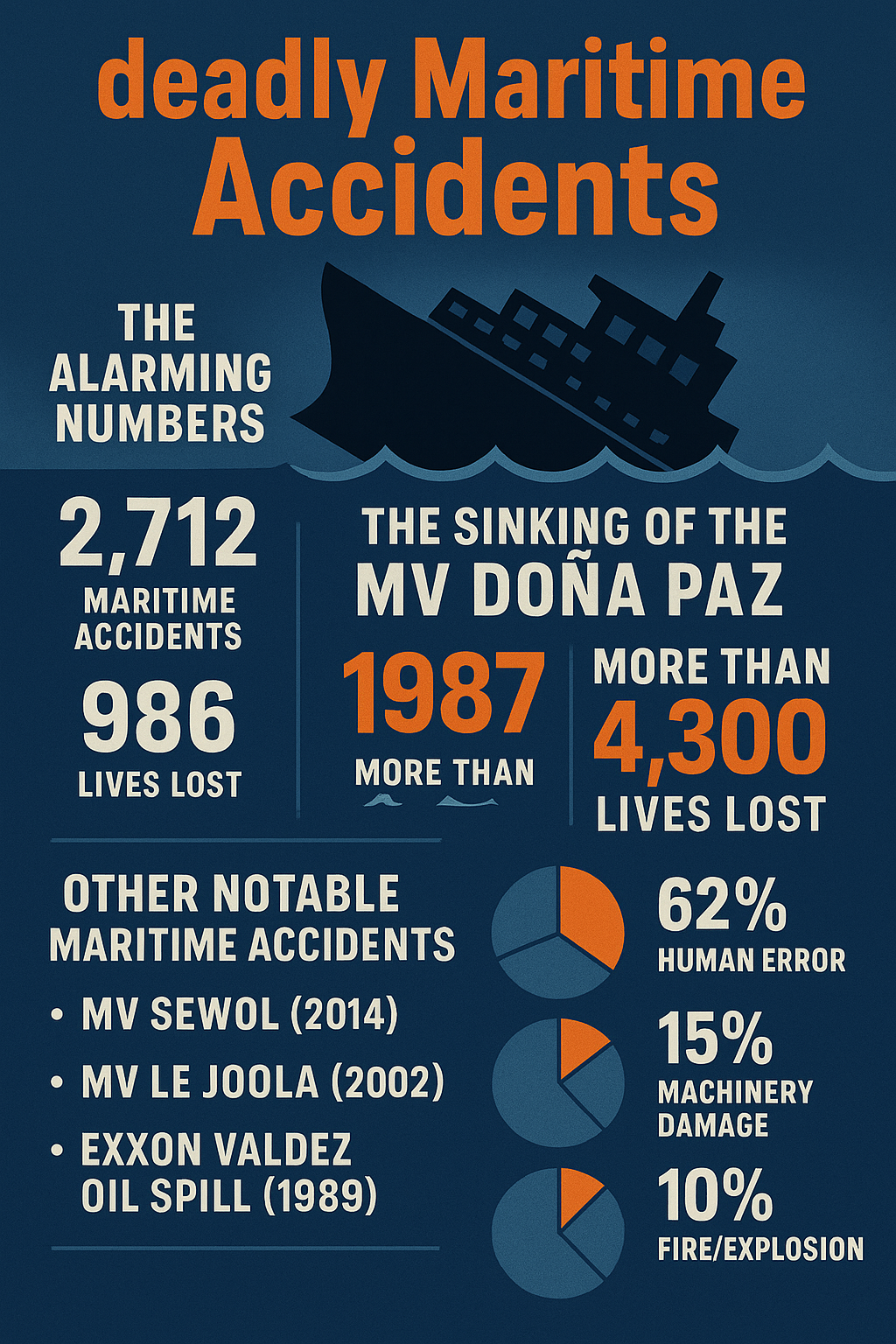

The Alarming Numbers

According to the International Maritime Organization (IMO), there were 2,712 reported maritime accidents in 2020 alone, resulting in 986 lives lost and over $1.4 billion in damages. The most common causes of these accidents include:

- Human error (62%)

- Machinery damage (15%)

- Fire/explosion (10%)

- Collision (6%)

- Weather-related incidents (4%)

The Sinking of the MV Doña Paz

One of the deadliest maritime accidents in history is the sinking of the MV Doña Paz in 1987. This Philippine-registered passenger ferry collided with an oil tanker and sank, resulting in the loss of over 4,300 lives. To put that number into perspective, it’s estimated that more people died in this single incident than in the Titanic disaster. The tragedy occurred on a routine journey, and many passengers were traveling home for the holidays. The exact number of fatalities may never be known, as many passengers were not registered. The incident highlights the importance of safety regulations and enforcement, particularly in regions with high passenger volumes.

Other Notable Maritime Accidents

- MV Sewol (2014): A South Korean ferry capsized and sank while carrying 476 passengers, mostly high school students, resulting in 304 deaths. The incident raised questions about safety protocols and emergency preparedness.

- MV Le Joola (2002): A Senegalese ferry capsized off the coast of Gambia, killing over 1,800 people. The tragedy was attributed to severe overcrowding and poor safety measures.

- Exxon Valdez Oil Spill (1989): While not a traditional maritime accident, this oil spill released millions of gallons of crude oil into Prince William Sound, Alaska, devastating the local ecosystem and wildlife.

Learning from the Past

Maritime accidents often result from a combination of human error, equipment failure, and adverse weather conditions. By studying these incidents and implementing stricter safety protocols, the maritime industry can reduce the risk of future accidents. Some key takeaways include:

- Improved safety training for crew members

- Regular maintenance and inspection of vessels

- Enhanced weather forecasting and warning systems

- Stricter regulations for passenger safety and cargo transport

Conclusion

As the world’s reliance on maritime trade continues to grow, so does the importance of prioritizing safety at sea. By understanding the causes and consequences of maritime accidents, we can work towards creating a safer and more responsible shipping industry. The stories of those who have lost their lives at sea serve as a poignant reminder of the importance of vigilance and preparedness.

Terror in the Modern Age: The Largest Attacks of the Past 50 Years

The past five decades have witnessed some of the most devastating terror attacks in modern history. These events have left deep scars on the global psyche, reshaping international relations, security protocols, and our collective sense of safety. Here’s a look at some of the largest terror attacks since 1970, ranked by their impact and the number of lives lost.

1. September 11 Attacks (2001)

The September 11 attacks in the United States are etched in global memory. On that fateful day, nearly 3,000 people lost their lives when hijacked planes crashed into the World Trade Center in New York City and the Pentagon in Washington, D.C. The attacks, orchestrated by Al-Qaeda, marked a pivotal moment in modern terrorism, leading to the launch of the War on Terror and significantly altering global security measures.

2. Paris Attacks (2015)

On November 13, 2015, coordinated attacks across Paris, France, left 130 people dead and over 350 injured. ISIS claimed responsibility for the attacks, which targeted the Bataclan concert hall, cafes, and restaurants. These attacks were a stark reminder of the reach of terrorism in Europe and led to a significant shift in security policies across the continent.

3. Mumbai Terror Attacks (2008)

The Mumbai terror attacks, carried out by Lashkar-e-Taiba, a Pakistan-based militant group, occurred on November 26, 2008. Over 166 people were killed, and more than 300 were injured in a series of coordinated shootings and bombings at various locations, including the Taj Mahal Palace Hotel. The attacks highlighted the vulnerability of major cities to well-planned terrorist operations.

4. Beslan School Siege (2004)

In September 2004, Chechen separatists took over 1,000 people hostage at a school in Beslan, Russia. The siege ended in a bloody confrontation that resulted in the deaths of at least 334 people, including 186 children. The Beslan tragedy remains one of the most horrific examples of terrorism targeting civilians, particularly children.

5. Bali Bombings (2002)

The Bali bombings on October 12, 2002, claimed the lives of 202 people, mostly tourists, and injured hundreds more. ISIS-linked militants detonated bombs in crowded nightspots in Bali, Indonesia. The attack was a significant blow to Indonesia’s tourism industry and marked a turning point in the country’s counter-terrorism efforts.

6. Oklahoma City Bombing (1995)

On April 19, 1995, Timothy McVeigh and Terry Nichols carried out the Oklahoma City bombing, killing 168 people and injuring over 680 others. The bombing of the Alfred P. Murrah Federal Building was one of the deadliest acts of domestic terrorism in U.S. history, highlighting the threat posed by extremist ideologies within the country.

7. Beirut Barracks Bombings (1983)

The Beirut barracks bombings on October 23, 1983, targeted the U.S. and French military barracks in Beirut, Lebanon. The attacks, which killed 299 people, were carried out by the Islamic Jihad Organization. These bombings were a significant factor in the withdrawal of multinational forces from Lebanon and remain one of the deadliest attacks on Western military forces in recent history.

8. Sri Lanka Easter Bombings (2019)

On April 21, 2019, a series of bombings targeting churches and hotels in Sri Lanka on Easter Sunday killed over 259 people and injured more than 500. The attacks, claimed by ISIS, were one of the most devastating acts of terrorism in recent years, targeting religious gatherings and tourist hotspots.

Conclusion

These attacks, among others, have had a profound impact on global politics, security measures, and societal attitudes. While the world continues to grapple with the threat of terrorism, understanding the nature and scale of these attacks is crucial in the ongoing fight against terror. As we reflect on these tragic events, it’s clear that the fight against terrorism requires a multifaceted approach, combining security measures with efforts to address the root causes of extremism.

The Oklahoma City Bombing, 1995 – A Nation in Mourning

Introduction: An Ordinary Morning Turned Tragic

On April 19, 1995, at 9:02 AM, a massive explosion ripped through downtown Oklahoma City, shattering windows, collapsing buildings, and sending shockwaves across the country. The bombing of the Alfred P. Murrah Federal Building became the deadliest act of domestic terrorism in U.S. history.

The Events of April 19, 1995

That morning, a truck packed with over 4,800 pounds of explosives was parked outside the Murrah Building. Moments later, it detonated, killing 168 people, including 19 children in a daycare center. More than 600 others were injured, and the explosion left a crater 30 feet wide. The entire north side of the building was destroyed, and over 300 surrounding buildings were damaged.

Rescue efforts continued for days as first responders and volunteers worked tirelessly to find survivors. The attack shocked the nation, proving that terrorism wasn’t just an external threat—it could come from within.

Who Was Responsible?

Timothy McVeigh, a former U.S. Army soldier, carried out the attack in response to what he saw as government overreach, particularly the handling of the Waco siege and Ruby Ridge standoff. He was arrested just 90 minutes after the bombing during a routine traffic stop. His accomplice, Terry Nichols, helped plan the attack. Both were convicted—McVeigh was executed in 2001, and Nichols received life in prison.

The Aftermath and National Response

The Oklahoma City bombing led to major security reforms. The Anti-Terrorism and Effective Death Penalty Act of 1996 strengthened law enforcement’s ability to prevent future attacks. Federal buildings nationwide increased security, and discussions around domestic extremism took center stage.

The attack also highlighted the resilience of the Oklahoma City community. Within hours, people rushed to donate blood, provide aid, and support first responders. The phrase “Oklahoma Standard” emerged, symbolizing acts of kindness and unity in the face of tragedy.

Honoring the Victims: The Oklahoma City National Memorial

Today, the site of the bombing is home to the Oklahoma City National Memorial & Museum, honoring those who lost their lives. The 168 empty chairs, arranged by floor and location, serve as a solemn reminder of the human cost of violence.

Lessons from the Oklahoma City Bombing

The bombing serves as a tragic reminder of the dangers of extremism and the importance of vigilance against hate-driven violence. But it also showcases the strength of a community determined to heal, rebuild, and ensure that such a tragedy never happens again.